North and South Reservoir Improvements

Project Status

Project Status

Click here to see status updates.

Project Details/Neighborhood

Water Reservoir

Background

The City receives its potable water from Seattle Public Utilities. Water is contained in two, 4.0-million-gallon steel reservoir tanks before being distributed to roughly 24,000 residents. Both tanks are similar in size and generally in good condition. The north tank was constructed in 1962 and the south tank was constructed in 1975. They are approximately 150 feet in diameter and 32 feet high. Both tanks were seismically enhanced in 1999 and the interior and exterior coatings were replaced in 2000-2001. Many tank components have aged or deteriorated since these upgrades were completed. After over 20 years, the interior and exterior coatings have reached the end of their useful life and are in need of replacement to protect the tanks.

Description

The design process for the replacement of the interior and exterior reservoir tank coatings and safety improvements such as installing new stairway access to the roof and a roof guardrail will be completed by the end of 2022. Additional improvements may include replacement of hatches, air vents, and cathodic protection. The construction timeframe will likely span two years to allow reservoir operations to continue during construction.

Construction Project Timeline (Target Completion Date)

Q2 2025

Project Budget

$7,119,602

Contact

Patrick Yamashita, City Engineer / PW Deputy Director: patrick.yamashita@mercerisland.gov

Status Updates

October 10, 2024

Photos:

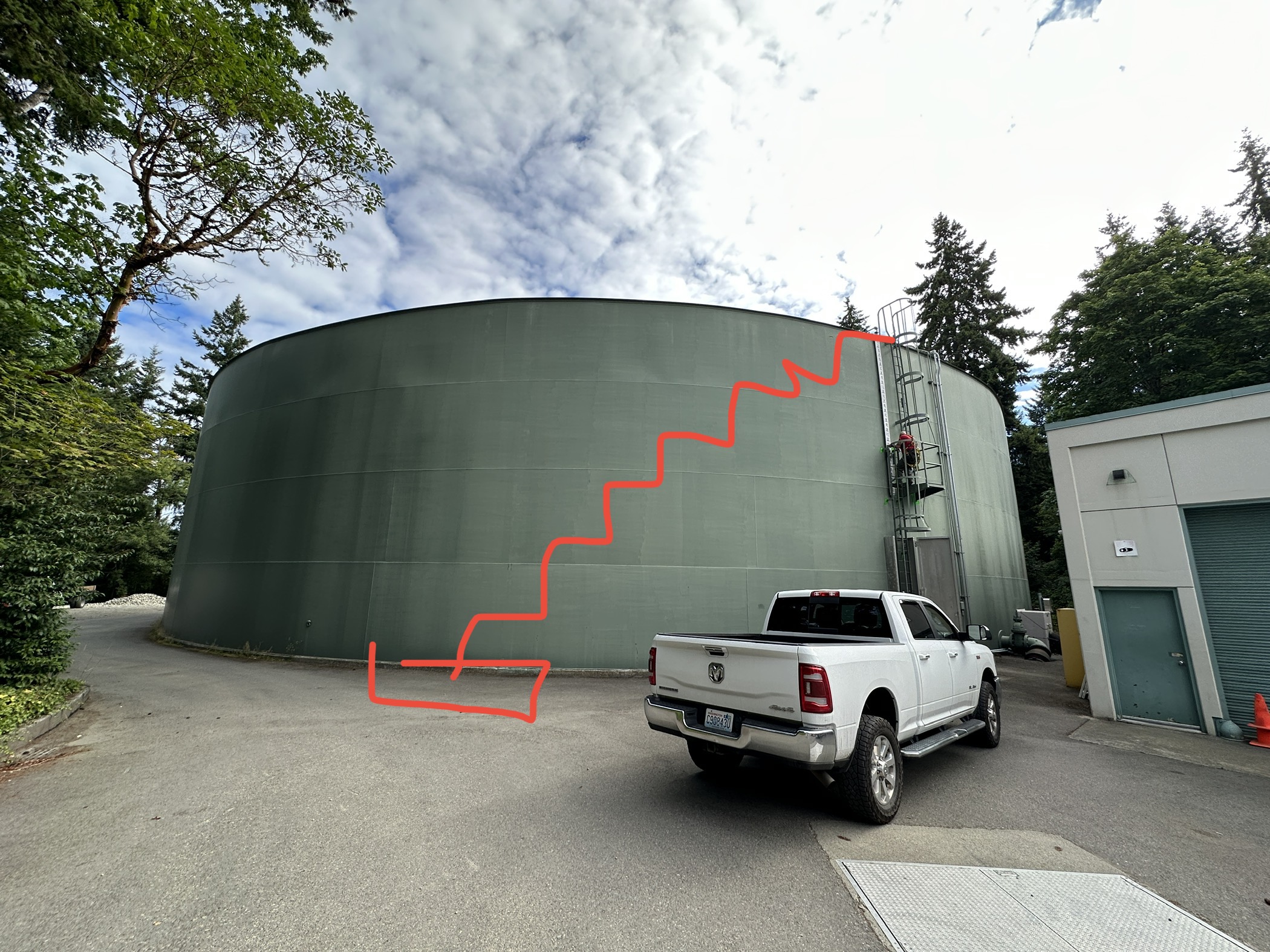

1. Door cut in from tank interior

2. Door from exterior

As painting continues on the north reservoir roof, work on the interior of the south reservoir began this week. The contractor has cut a temporary door into the south reservoir to provide access to large equipment and materials. The contractor will begin paint removal on the interior and then shift to spot welding structural roof support elements.

September 2024

Photos:

- North Tank Roof Blast & Prime 1

- North Tank Roof Blast & Prime 2

Work continues on the north reservoir roof. Priming has begun with painting to follow. Painting should be completed by the end of September.

August 8, 2024

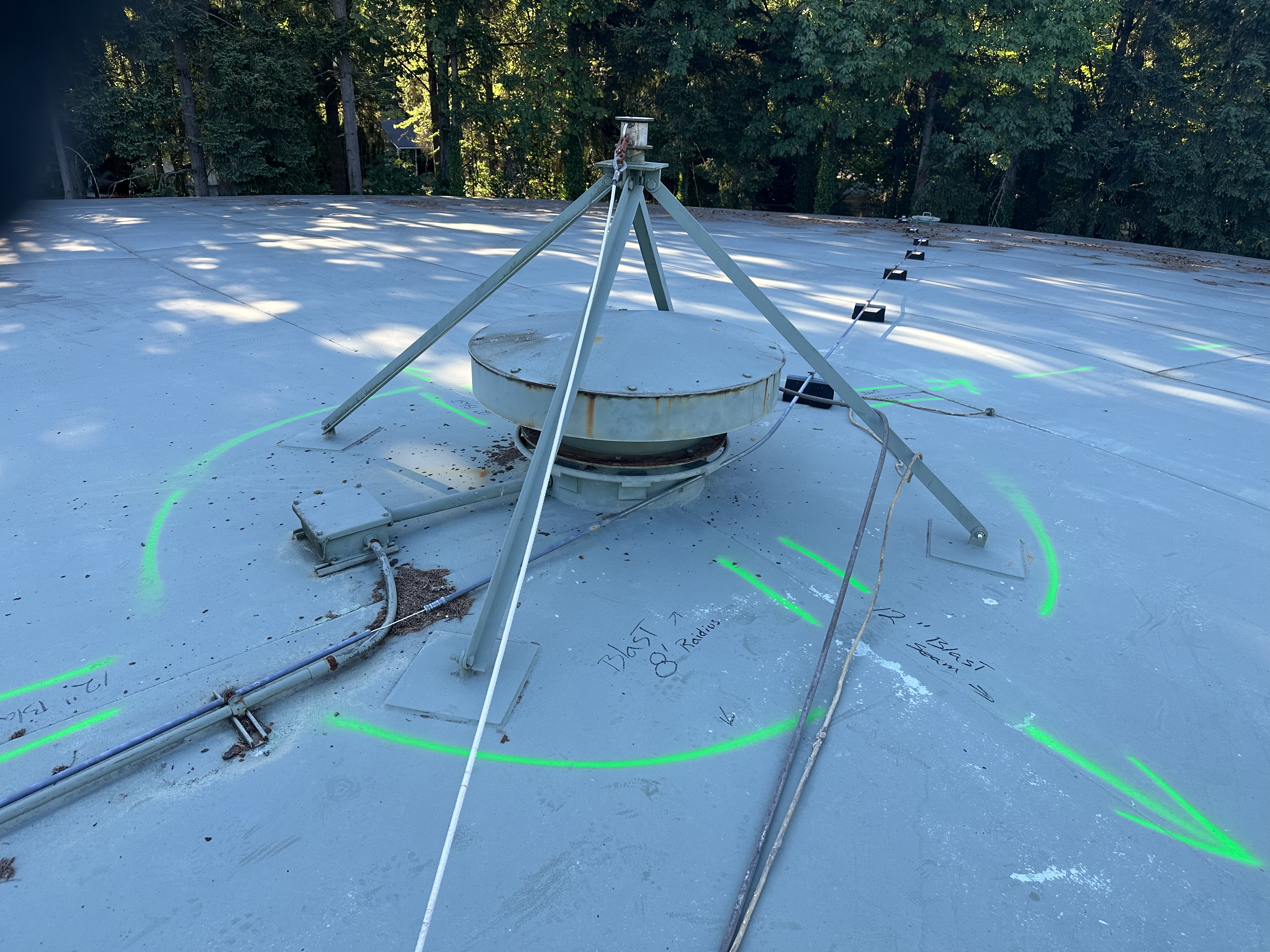

Photos:

- Reservoir Roof

- Roof Encapsulation

The contractor began surface preparation of the north reservoir roof through sand blasting this week. Priming and painting will begin in a few weeks. The extent of spot repair is significantly more extensive than anticipated. The team took this opportunity to change surface preparation methods from spot grinding to sand blasting of the entire roof to provide a greater value and to double the life span of the coating compared to spot repair. It will also remove all existing lead-based paint. The roof is fully encapsulated to keep sand blasting materials from being released to the atmosphere. This approach will also be taken on the south reservoir roof next spring. Both will be addressed through change orders.

June 6, 2024

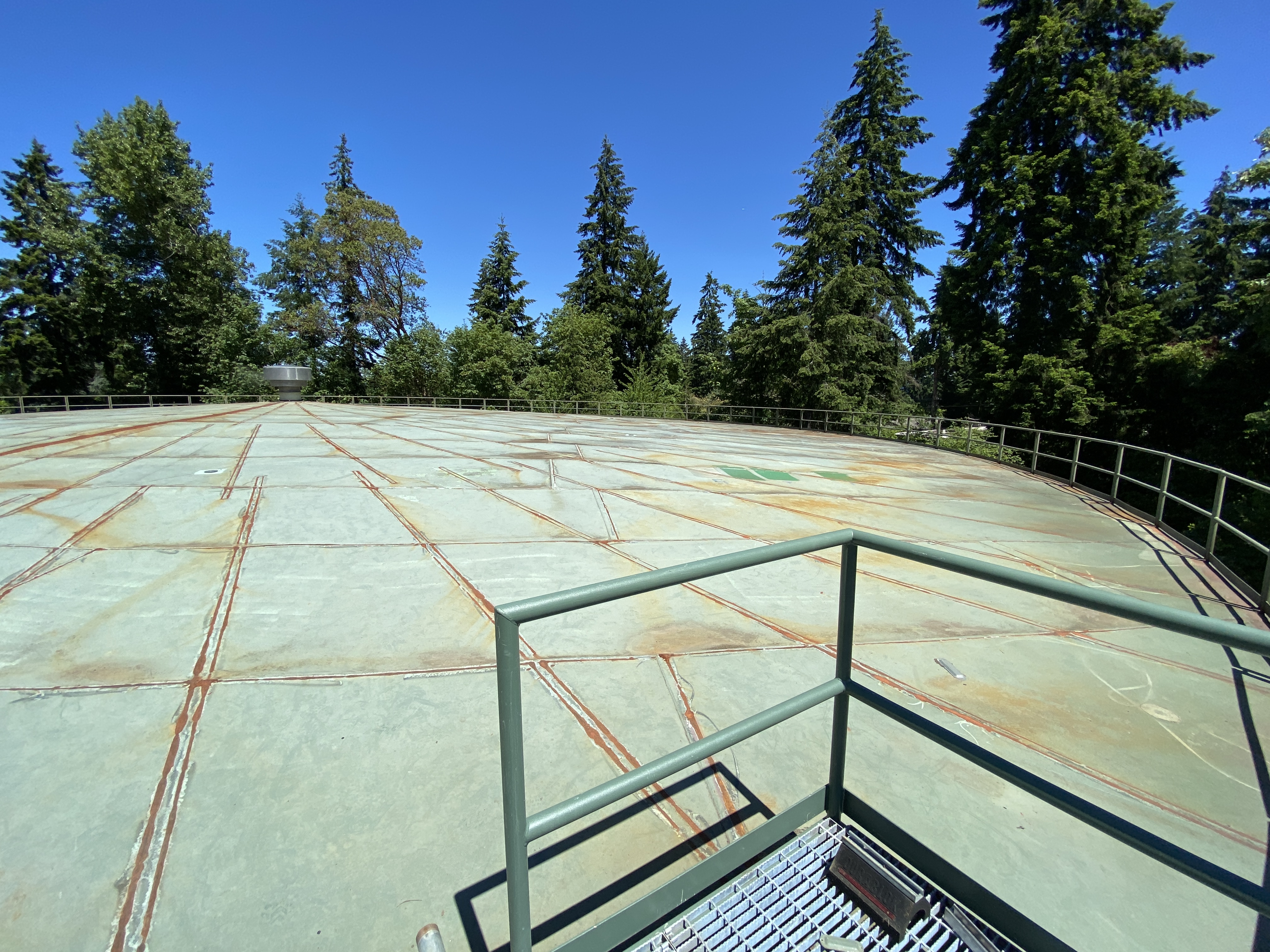

Photos:

- North Reservoir freshly painted

- North Reservoir uncoated roof

- South Reservoir existing condition

The interior coatings in the north reservoir were completed in May. After the necessary testing protocols passed, the reservoir was refilled and put back into service on Friday, May 24. May was a busy month as the exterior walls of the reservoir were also recoated. Photo 1 shows the recoated exterior of the north reservoir. Next up is the surface preparation and painting of the north reservoir roof. The extent of surface preparations needed is significantly more than originally expected due to an increase in weld replacements to ensure the long-term structural integrity of the roof. See photo 2 for the current condition. Work on the interior and exterior of the south reservoir will likely begin in the fall. Photo 3 shows the current exterior of the south reservoir.

April 19, 2024

Photos:

North tank before painting

North tank after painting

Painting on the interior of the north reservoir is wrapping up in the next week or so, then the painted surfaces will be cured and tested, followed by disinfection, and refilling of the tank. Prior to putting the reservoir back in service, the water must be tested. If all goes well, the north reservoir tank will be back in service in mid-May. Once the interior work is complete, the contractor will shift efforts to preparing the exterior of the north tank for painting.

February 29, 2024

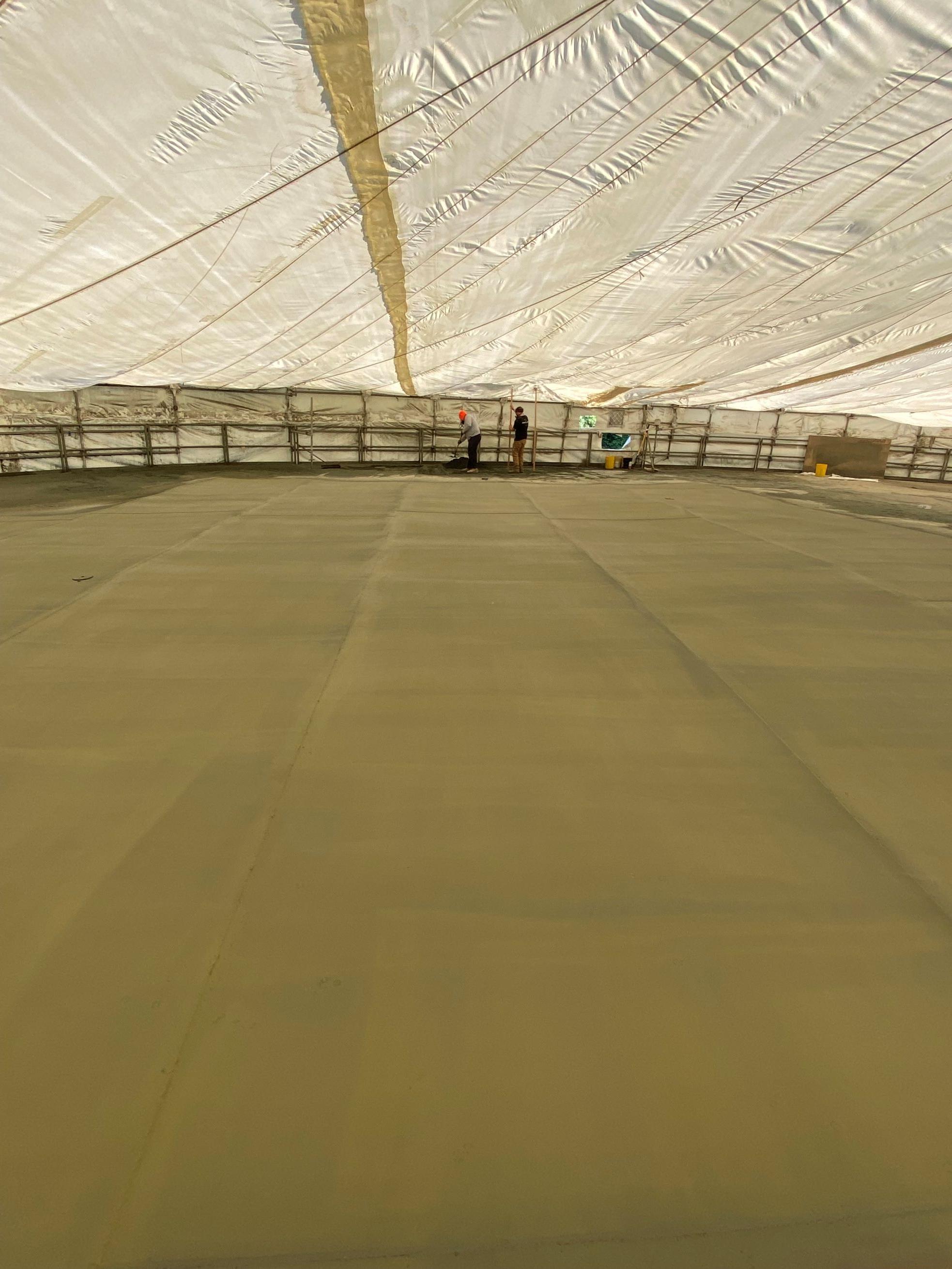

Photo 1 - north tank sand blasting

Photo 2 - north tank particulate separator

Work on the north reservoir interior continues. The contractor is wrapping up the last of the sandblasting and has begun primer coating the interior of the tank. Photo 1 shows the inside of the north tank during sand blasting and photo 2 shows the particulate separator that filters the airborne blastings without any material getting into the atmosphere. Painting of the tank interior will continue at least through March

January 18, 2024

Photo 1: North Tank Interior

Photo 2: Roof Structural Welds

The exterior stairway, roof railing and rain gutter systems are complete on both reservoir tanks. The major sandblasting of the north tank interior is complete along with weld reinforcement of the roof. This week, work inside the north tank transitioned to paint preparation. The painting stage will continue for the next several months and will be completed in time to refill the tank for operation as water system demand increases in late spring. Refer to the photos of the tank interior and roof structural welds

November 2023 Update

Photo 1 – spot welding roof structural members (north reservoir)

Photo 2 – roof structural members (north reservoir)

Photo 3 – existing roof with new railings in background (north reservoir)

Photo 4 – existing ladder (south reservoir)

Photo 5 – new stairway (south reservoir)

North reservoir – Spot welding of the structural members supporting the roof continues in preparation for final sand blasting and application of the new protective coating for the interior of the reservoir. The interior coating will be completed by early spring, ahead of peak water demand season when the north tank will be put back into service.

South Reservoir – The ladder style maintenance access to the roof was removed and replaced with a stairway to increase safety and improve access to the roof for maintenance crews.

October 2023 Update

Photo 1: North Interior

Photo 2: South tank railing and gutter

Work on the $7 million reinvestment in our two 4-million-gallon water reservoirs continues with installation of roof railings and gutters along with an exterior stairway to replace the old ladder. Sand blasting of the interior of the north tank started this week and will continue for 2 to 3 weeks. It will prepare the steel tank surface to receive the new protective coating.

September 2023 Update

Residents near the project will be receiving a postcard mailer with information about the project. Most of the 1.5 year construction will proceed without much impact to the neighborhood. However, the first phase of work involves installing the stairways and railings. This will create noise due mostly to hammering. This work will last approximately two weeks. Once this phase of work is completed, the remaining work will generally be less noisy.

Copy of the mailer: 9.20.23 Mailer

August 2023 Update

Photo 1: New Stairway Location

Photo 2: Rooftop Vent to be Replaced

Photo 3: Preparation for Temporary Entry into Reservoir Tank

Construction on the reservoir tanks has started. In the coming months, the stairway and railing safety improvements will be installed along with a new access hatch for the north reservoir. One of the reservoirs will be drained and taken out of service this fall and winter to allow the contractor to replace the interior coating. The interior coating of the other reservoir will be replaced the following fall and winter.

June 2023 Update

This $7 million investment in our water reservoirs is one of several projects that will maintain and improve our critical infrastructure at the reservoir site. This facility is considered the “heart” of the water system and is critical for the safe and efficient delivery of water to our residents. Other projects include the soon to be completed Booster Chlorination System, Booster Pump Station Generator Replacement, and Reservoir Pump Replacement projects. Permits for the stairway and railing safety improvements are in hand and the work on the tank exteriors is expected to commence later this month.

February 2023 Update

The project design was completed in early December and advertised for construction bids. Three bids were received. The lowest responsive bidder was Paso Robles Tank, Inc. (PRT) from Hemet, California. The City Council awarded the contract to PRT on February 7, 2023 and set the total project budget at $7,119,602. Construction will begin at the reservoir site this spring and is expected to be completed in early 2025

November 2022 Update

Photo 1 – Existing ladder to be replaced with stairway to improve safety

Photo 2 – Edge of reservoir roof where guardrail will be installed

The 90% design was received from the consultant in November. The 100% design will be completed and the project advertised for construction bids in December/January. The construction timeframe is expected to span two years starting in Q1 2023.

May 2022 Update

The consultant has provided an updated schedule. Based on this, 50% design is estimated to be submitted to the City for review in a couple of months.

April 2022 Update

The City finalized the list of reservoir improvements to be included in this project and design will start in May.

February 2022 Update

Photo 1- Outside visual level indicator on tank

Photo 2- Visual level indicator weight on the inside of the drained tank

The City uses visual level indicators to determine tank levels on both reservoirs, which use a weighted cable and float system that adjusts to the level of water in the tank. During the last winter storm, staff recently discovered that this mechanism was providing inaccurate readings of the actual amount of water in the south tank. The City will soon be finalizing the list of improvements to incorporate into design and will look at changing how the tank levels are read.

November 2021 Update

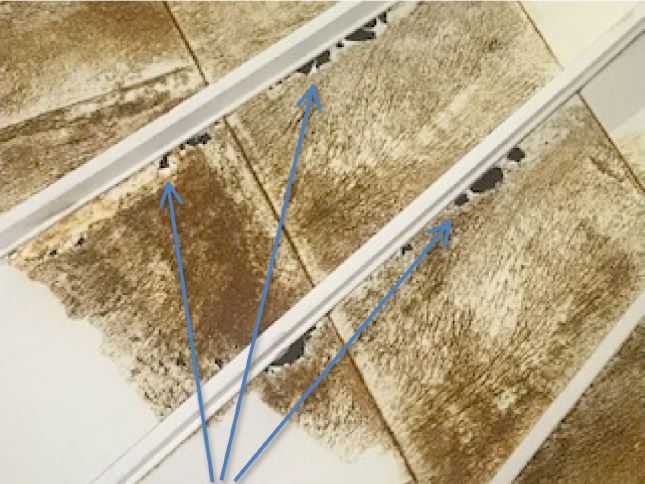

Photo 1- Grout at the bottom edge of tank base

Photo 2- Cathodic protection system anode

Photo 3- Exterior tank topcoat

Photo 4- Interior coating corrosion on ceiling

In October, the City received the draft report from RH2 Engineering. There are no required structural improvements needed and condition assessments show both tanks, excluding coatings, to be in overall good condition.

The report provided recommended improvements to protect structural integrity, safety, and longevity. Potential improvements include replacing the outside grout around the bottom edge of the tank base, replacing the interior coating’s cathodic protection system, and replacement of interior tank coatings. The tank exteriors on each reservoir are holding up well and are good candidates to have an over-coat done.

The City has received the final report from RH2. Actual design additions will be discussed internally with design taking place shortly after.

September 2021 Update

Photo- Tank Assessment

The City selected RH2 Engineering as the design consultant and a contract was started in June 2021. The City drained the south reservoir in the middle of June and RH2 performed an inspection of the interior and exterior of the tank. The hot weather prevented draining of the north tank so a raft inspection took place in July instead. RH2 is now wrapping up the summary report which details the condition of the reservoirs, required structural upgrades, and suggested recommendations.